|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

Cirrus Monthly Proficiency Program

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The power lever in the cockpit controls airflow to the engine cylinders by adjusting a throttle plate in the intake manifold. As you move the power lever between full and idle power, the throttle mechanism on the engine adjusts the airflow accordingly.

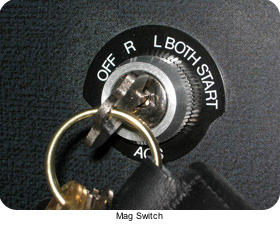

The ‘spark’ in the combustion equation comes from a dual ignition system powered by two magnetos. Each magneto functions as a generator and distributor cap combined in a single, engine-driven unit that sends a pulse of electricity to a spark plug in the cylinder. Each cylinder has two plugs that fire simultaneously, creating more efficient combustion and providing redundancy. The only way for the pilot to control the ignition is with the magneto selector.

|

Fuel is the last part of the engine’s

power requirement. Stored in wing tanks, 100LL grade aviation gasoline

travels to the engine through a fuel selector, multiple strainers,

and an engine-driven fuel pump. The fuel pump also incorporates

a mixture control valve, allowing the pilot to compensate for variations

in air density according to altitude. A throttle metering valve

then adjusts the fuel flow according to the power lever position,

while a distribution system injects the correct amount of fuel directly

into the intake valve chambers of the cylinders. |

|

| Page 2 |

Cirrus Monthly Proficiency Program

March—Feel the Burn:

Engine Monitoring and Management

THE FIRE-BREATHING

BEAST (continued)

The essence of engine management is

controlling and monitoring airflow, fuel flow, and combustion

through pilot-controllable

adjustments. You will know what effect your adjustments have

had by taking advantage of your airplane’s engine monitoring

capabilities:

|

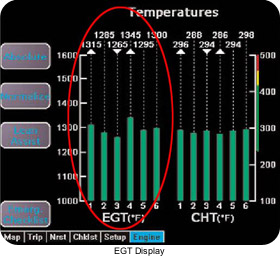

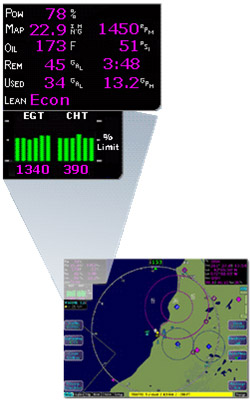

Exhaust Gas Temperature (EGT) – In most Cirrus airplanes, each exhaust manifold has a thermocouple that sends information about exhaust temperature to instruments in the cockpit. The MFD can display this information through map page data blocks or on the engine page. |

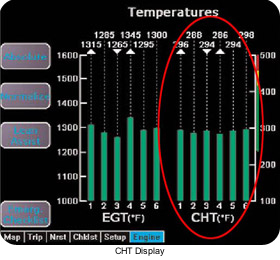

Cylinder Head Temperature (CHT) – Again, in most Cirrus airplanes each cylinder has a temperature probe that relays information to the cockpit. These temperatures are also displayed on the MFD through the map or engine page. |

|

|

Fuel Quantity Indicators – Two gauges, located near the fuel selector knob, indicate the fuel quantity in the fuel tanks. Ideally, the total on-board fuel according to the gauges will be the same as the “Fuel Remaining” value on the EMax page. |

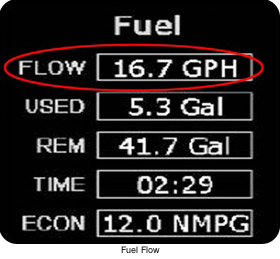

Fuel Flow – A pressure sensor in the fuel system determines the fuel flow, measured in gallons per hour (gph). This information can be displayed throughout the cockpit depending on your avionics options. |

|

| Page 3 |

Cirrus Monthly Proficiency Program

March—Feel the Burn:

Engine Monitoring and Management

THE FIRE-BREATHING BEAST (continued)

|

Oil Temperature – Another temperature probe monitors oil temperature in the engine and displays the information on the MFD or analogue instruments. |

Oil Pressure – A sensor in the engine monitors engine oil pressure and displays it on the MFD, PFD, and analogue instruments depending on the Cirrus model. |

|

|

Manifold Pressure – A sensor between the intake valves and the throttle body monitors manifold pressure. Again, depiction of this information will vary according to your specific airplane’s avionics options. |

Engine RPM – Engine and propeller RPM can be displayed on the MFD, PFD, and analogue gauges. |

|

|

Percent Power – The MFD uses the RPM, fuel flow, manifold pressure, and outside air temperature to determine the percentage of rated power being produced. This is displayed on the MFD and PFD. |

| Page 4 |

Cirrus Monthly Proficiency Program

March—Feel the Burn:

Engine Monitoring and Management

![]()

LEAN AND MEAN

Perhaps the most feared and least understood engine

management procedure is engine leaning. While most pilots know that leaning

is necessary, not all understand why it’s required or what’s

happening in their engines.

First, leaning is a must because the correct fuel-to-air ratio is a function of mass. As a plane climbs higher, the air gets thinner and weighs less for a given volume. In order to achieve the ideal combustion process, less air mass means that the engine needs less fuel mass. The pilot controls the fuel-to-air ratio with the mixture control and can adjust the fuel flow precisely for performance at altitude.

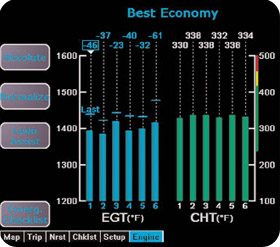

If you reference the POH for your Cirrus airplane, you will notice that two types of leaning are mentioned in the performance charts: Best Power and Best Economy. Understanding what these leaning targets represent is vital to truly mastering the engine management process. Quite simply, a Best Power mixture results in the most possible power considering the fuel and air available. Best Economy, on the other hand, provides the most power per gallon of fuel burned.

|

|

NOTE! Best Power = Most power and fastest speed. (Highest Brake Horsepower) Best Economy = Most horsepower per gallon, more range, and less fuel consumption. (Lowest Brake Specific Fuel Consumption) |

||

| Page 5 |

Cirrus Monthly Proficiency Program

March—Feel the Burn:

Engine Monitoring and Management

![]()

LEAN AND MEAN (continued)

As you lean from full rich, the EGTs will initially

rise. If you continue leaning smoothly and slowly, there will be a distinct

point where the temperatures momentarily pause before beginning

to drop.

Quite

simply, the peak is the point at which the fuel-to-air ratio burns

the hottest. On the rich side, excess fuel causes the EGTs to

be lower than peak, while

on the lean side there isn’t enough fuel to burn at the hottest temperatures.

This concept is important because Best Power and Best Economy respectively

are on the rich side and lean side of peak EGT.

|

|

Your Cirrus POH states, “For “Best Power” use 75% power or less. For “Best Economy” use 65% power or less.” For settings above these values, lean according to the fuel flows listed in the Performance section of your POH. |

||

|

| Page 6 |

Cirrus Monthly Proficiency Program

March—Feel the Burn:

Engine Monitoring and Management

![]()

KEEPING THE TANKS FULL

|

Perhaps the single most common cause of engine failure is fuel exhaustion. Your knowledge of engine monitoring and management directly relates to your ability to keep fuel in the tanks and the propeller turning. Luckliy, the Cirrus offers many more fuel management tools than the average airplane.

|

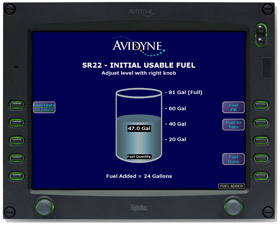

Your fuel management success begins when you initialize your MFD and enter the starting fuel quantity. Make sure that the value entered on the fuel page is the same amount that you have in your tanks. The easiest way to guarantee that they are the same is to top off or fill to the tabs. As you fly, the ‘fuel remaining’ feature on the EMax should agree with the numbers on the analogue gauges. A discrepancy may indicate a leak or incorrect initial fuel quantity. |

Fuel Remaining and Fuel Gauges |

|

You can quickly determine how much longer the engine will run on the current amount of fuel by looking at the EMax ‘Time’ feature, found under the Fuel label. You can use this to calculate holding times, diversion requirements, and fuel reserves. |

Perhaps the most powerful fuel management tool available to you is the ‘Fuel Remaining’ feature on the Map and Trip pages of the MFD. Using current groundspeed, waypoint and course distances from the GPS, and fuel information from EMax, the MFD calculates the remaining fuel at each of the waypoints in the flight plan. This feature allows you to immediately see how power and mixture adjustments will affect your fuel status. |

Fuel Remaining |

|

|

Remember that the Fuel Remaining information is based on your current groundspeed. Changes in head- or tailwind components will change the quantity of fuel predicted to remain at your waypoints and destination. |

||

| Page 7 |

Cirrus Monthly Proficiency Program

March—Feel the Burn:

Engine Monitoring and Management

![]()

A FEW SIMPLE SUGGESTIONS

Engine monitoring and management should be very simple and routine

in most situations. Actual inputs and adjustments are relatively

uncommon in cruise flight assuming that the airplane was properly configured

initially.

As you practice and maintain good engine management habits, follow

these tips to maximize your efficiency:

- Always remember to lean the mixture in cruise flight.

- Use the lean assist function to enhance accuracy and precision.

- Consider flying high enough to reduce maximum power production to 65% or less and leaning for best economy.

- Use on-board weather resources and the PFD wind vector to find an altitude with the most favorable winds for each route section.

- Set a message timer on the GPS to remind you to change fuel tanks every 30 minutes.

- Include the engine gauges in your scan and watch for changes in indications that weren’t caused by changes in engine control or operating conditions.

- Develop personal fuel minimums considering personal ability, weather conditions, geographic location, availability of alternates, etc.

- Continually monitor winds aloft and fuel burn to ensure that you will arrive at your destination with sufficient fuel to meet your personal minimums.

- Develop and use positive engine monitoring and management habits.

| Page 8 |

Cirrus Monthly Proficiency Program

March—Feel the Burn:

Engine Monitoring and Management

![]()

Can You correctly monitor fuel during flight?

Take the Pilot's World Challenge to find out:

| Page 9 |

Cirrus Monthly Proficiency Program

March—Feel the Burn:

Engine Monitoring and Management

![]()

NTSB ACCIDENT REPORT

Now that you’ve learned about the importance

of the autopilot as a tool to manage workload and expand your Single Pilot

Resource Management

skills, click on the following link to review an NTSB Accident

Report:

Analyze the accident. Think about how the proper engine and fuel management might have helped prevent the accident.

- How did the pilot’s lack of leaning procedures affect his flight?

- What procedures discussed in this month’s Pilot’s World might have led to a more desirable outcome?

- What systems on a Cirrus might have helped the pilot maintain better situational awareness?

- How might the avionics on a Cirrus have provided a clear indication that there wasn’t enough fuel remaining to reach the destination?

![]()

| Page 9 |

Cirrus Monthly Proficiency Program

March—Feel the Burn:

Engine Monitoring and Management

![]()

OBJECTIVE

This month’s flight segment asks

you to demonstrate excellent engine and fuel management skills

during your flight activities.

The objective is to practice and reinforce proper use of the

engine monitoring and management systems in real- world flight

scenarios.

Complete the following engine management exercises by incorporating them into your flight activities. Ideally, you will complete these exercises with a CSIP instructor on board to help critique and assess your performance. Always maintain situational awareness and never compromise the safety of yourself or others.

Flight activity items to complete:

- Complete a Personal Weather Minimums assessment.

- Obtain a thorough pre-flight weather briefing.

- Make an appropriate go/no-go decision for the flight.

- Precisely determine the amount of fuel required to fly to an airport approximately 30 minutes away.

- During flight, use the engine monitoring system to:

- Determine the accuracy of your flight planning.

- Practice leaning for Best Power and Best Economy, following the limitations listed in your POH.

- Observe how fuel consumption is influenced by improper leaning procedures (Note how fuel flow changes when the mixture is left full rich).

![]() For

a Printable PDF version of this information, CLICK HERE.

For

a Printable PDF version of this information, CLICK HERE.

![]()

| Page 13 |

Cirrus Monthly Proficiency Program

March—Feel the Burn:

Engine Monitoring and Management

![]()

You will successfully complete the March Cirrus Monthly Pilot

Proficiency program when you have gained a thorough understanding

of engine and fuel monitoring and management. Additionally,

you will understand how to properly use the monitoring and

management resources and controls available in your Cirrus

airplane.

Thanks for visiting Cirrus Pilot’s World and taking the March Monthly Proficiency Program. We hope you enjoyed the experience and that it has helped to increase your awareness, skill and proficiency in safely flying your Cirrus SRV, SR20 or SR22. Please take a moment to give us your feedback about this month’s course. Your suggestions will help us provide you with courses to improve your all-around flying safety and enjoyment Write to us at: pilotsworld@cirrusdesign.com. See you next month!

|

| Page 14 |

Traditionally,

engine management in piston singles involved a fair amount

of guesswork and many approximations. With modern engine

management systems, pilots now have the opportunity to

be precise in both management and monitoring.

Traditionally,

engine management in piston singles involved a fair amount

of guesswork and many approximations. With modern engine

management systems, pilots now have the opportunity to

be precise in both management and monitoring.

Once

upon a time, pilots would lean for Best Power by watching

inaccurate RPM gauges and Best Economy by engine ‘feel’.

With individual EGT and CHT probes in each cylinder, Best

Economy

and Best Power are no longer guesstimates. In fact, the Avidyne

Emax Lean Assist function will give you precise feedback

as you lean, even announcing when you have reached Best Power

and Best Economy.

Once

upon a time, pilots would lean for Best Power by watching

inaccurate RPM gauges and Best Economy by engine ‘feel’.

With individual EGT and CHT probes in each cylinder, Best

Economy

and Best Power are no longer guesstimates. In fact, the Avidyne

Emax Lean Assist function will give you precise feedback

as you lean, even announcing when you have reached Best Power

and Best Economy.